5S Projects

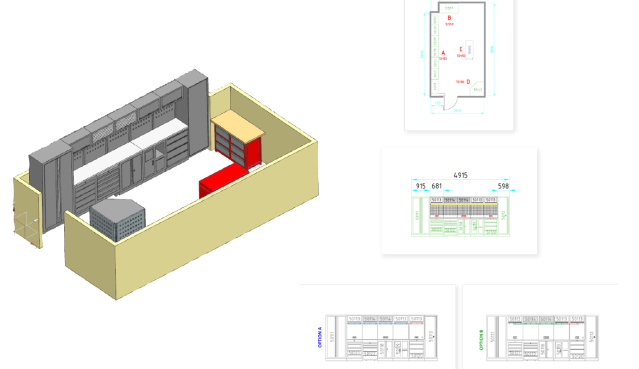

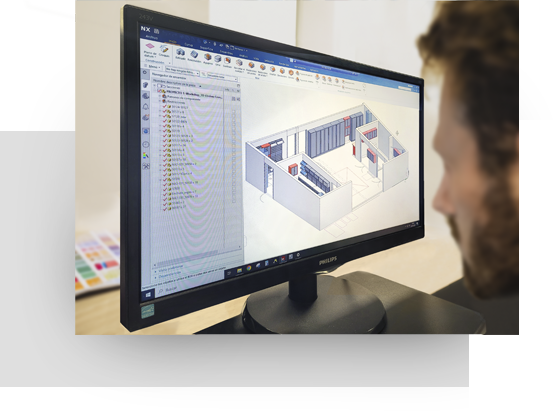

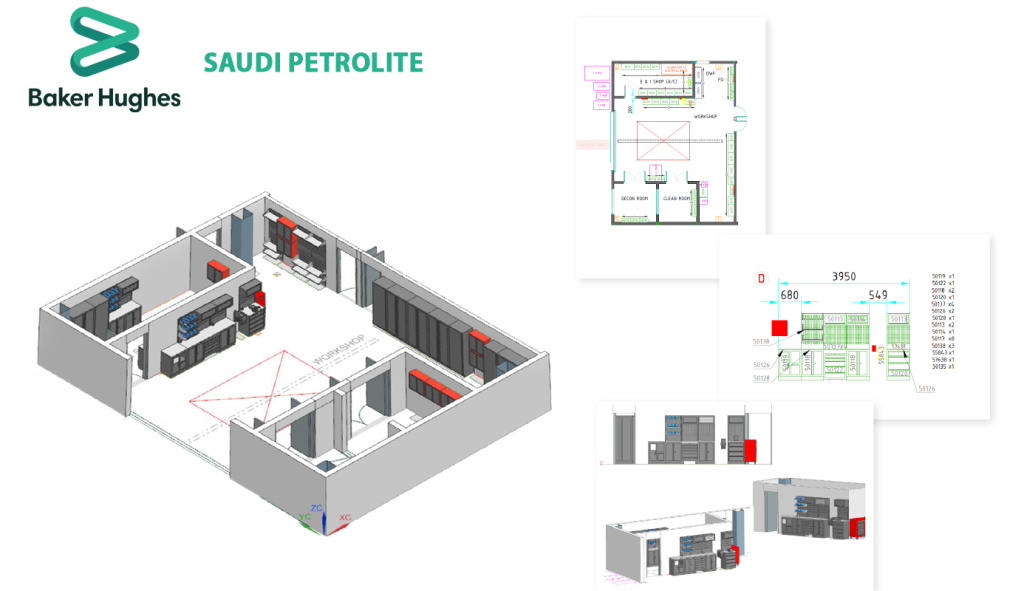

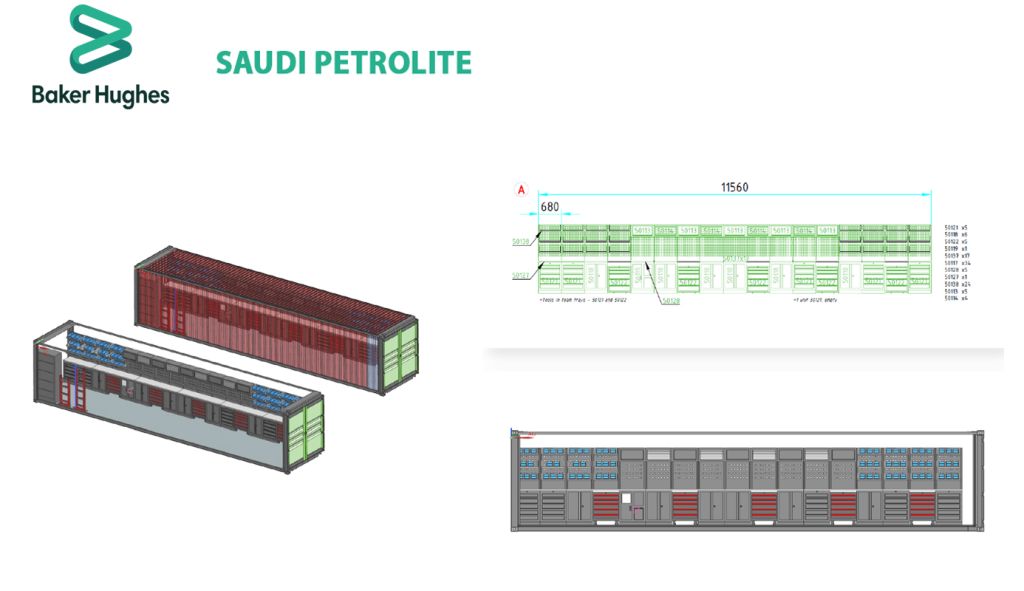

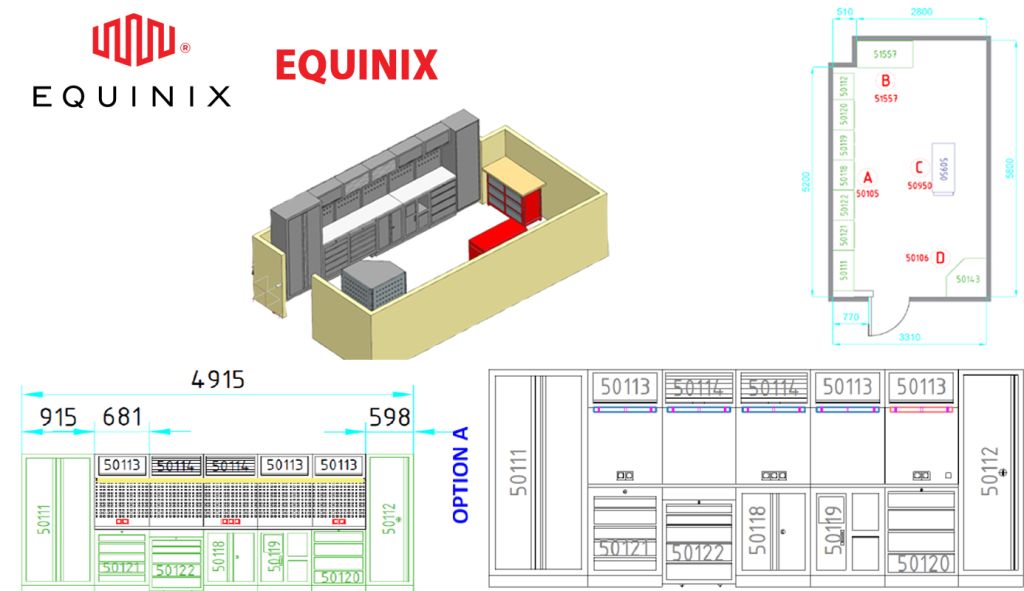

Solutions

Customized Solutions for Total Efficiency

- EGA Masters customized projects with a 5S approach, from conception to final delivery, maximizing safety, efficiency, and productivity in the most demanding environments. The term 5S comes from the acronyms: SEIRI (Sort), SEITON (Order), SEISO (Clean), SEIKETSU (Standardize), and SHITSUKE (Discipline)

What Do We Offer?

1. Comprehensive design of area control and tool distribution

From preliminary analysis, through design and development, to the implementation of complete turnkey solutions.

2. Customized Bi-Color Tray

The tools fit perfectly into the tray, which, thanks to the two colors used, allows you to see at a glance which tool is missing at any given time.

3. Custom marking

EGA Master offers the option of marking or laser-engraving tools with different logos or numbers to identify the company, division, or team to which they belong, thus avoiding typical tool shortages.

4. Inventory Management Software

Integration of systems that facilitate the control of tools and materials, reducing downtime and losses.

5. Color-Coding

It promotes standardization and visual order, allowing the instance to detect if any tool is missing from its site. This improves order, efficiency, and anomaly detection.

Advantages

- Greater Safety: Organized and risk-free environments.

- Operational Efficiency: Optimization of time and resources.

- Constant Quality: Standardized processes and uniform results.

- Costs Reduction: Less waste and better use of resources.

Projects

Contact us

to find out how we can help you

- You can send a message using the following contact form

- (*) Required fields