INTRINSIC SAFETY

INTRINSIC SAFETY

- TOOL CONTROL SYSTEM

-

TOOLKITS

- UNIVERSAL SETS

- INDUSTRIAL MAINTENANCE SETS

- AVIATION SET

- SETS FOR AUTOMOTIVE

- HYBRID / ELECTRIC VEHICLE MAINTENANCE SET

- SETS FOR MECHANICS

- PLUMBING AND CONDITIONED AIR SETS

- ELECTRICIAN SETS

- WIND POWER SETS

- ELECTROMECHANICAL KIT

- BUILDING MAINTENANCE

- professional SETS FOR MECHANICS

- professional PLUMBING SETS

- professional ELECTRICIAN SETS

- TRAYS

- MODULAR INDUSTRIAL FURNITURE

- WALL CABINETS

- TALL CABINET

- DISPLAY PANEL

- WORKBENCHES

- WORKBENCHES WITH VERTICAL PANEL

- WORKBENCH TROLLEYS

- ROLLER CABINETS 100% INOX

- INOX SURFACE ROLLER CABINETS*

- ROLLER CABINETS

- MOTORIZED WHEEL

- TROLLEYS WITH SHELVES

- JOBSITE BOXES AND CHESTS

- TOOL BOXES AND ACCESORIES

- BAGS, POUCHES BACKPACKS AND VESTS

- View all categories

- PLIERS AND PINCERS

-

GEAR PULLERS

- 3 JAW GEAR PULLER 2 POSITION

- 3 JAW REVERSIBLE GEAR PULLER 2 POSITION

- 2 JAW GEAR PULLER 2 POSITION

- UNIVERSAL 2 JAW GEAR PULLER

- UNIVERSAL 6 JAW GEAR PULLER

- UNIVERSAL 4 JAW GEAR PULLER

- UNIVERSAL 3 JAW GEAR PULLER

- 3 JAW GEAR PULLER

- 2 JAW GEAR PULLER

- 3 JAW LIGHT GEAR PULLER

- 2 JAW LIGHT GEAR PULLER

- BALL JOINT PULLER

- BEARING SEPARATOR

- SET OF BEARING SEPARATORS

- HYDRAULIC PULLER

- View all categories

- SCREWDRIVERS

-

BITS

- BITHOLDER SCREWDRIVERS

- TORQUE SCREWDRIVER

- CORDLESS SCREWDRIVER

- RATCHET FOR HEXAGONAL BITS

- REVERSIBLE RATCHET WRENCH (SOCKETS AND BITS)

- REVERSIBLE RATCHET HANDLE

- BALL RETAINER ADAPTER

- ADAPTER BIT FOR IMPACT SOCKETS

- MASTERBIT

- MASTERBIT TORSION

- MASTERBIT NON-SLIP

- MASTERBIT TIN

- MAGNETIC BIT HOLDER

- SET

- DISPLAYS

- IMPACT SCREWDRIVER

- MASTERBIT IMPACT 5/16"

- SOCKET BITS

- IMPACT SOCKET BITS

- View all categories

- ADJUSTABLE WRENCHES

-

WRENCHES

- MASTERGEAR

- MASTERGEAR REV.

- MASTERGEAR JOINT

- MASTERGEAR STUBBY

- MASTERGEAR DOUBLE

- Mastergear displays

- MASTERGEAR E-TORX®*

- RAPID WRENCH

- CLASSICGEAR

- CLASSICGEAR JOINT

- OPEN-END WRENCHES

- 15º AND 75º MICROMECH OPEN END WRENCHES

- COMBINATION WRENCHES

- EXTRA-LONG COMBINATION WRENCHES

- MAXI COMBINATION WRENCHES

- DOUBLE OFFSET RING WRENCHES

- 6 SPANNER DEMO KIT

- SLIM OPEN-END WRENCHES

- SLIM DOUBLE RING WRENCHES 15º BENT

- SLIM FLAT DOUBLE RING WRENCHES

- COMBINATION DEEP OFFSET SPANNER

- DOUBLE ENDED FLAT RING SPANNER

- HALF MOON

- FLARE NUT

- OPEN-END

- SINGLE ENDED OPEN JAW SPANNER

- TOTAL SAFETY SLOGGING WRENCHES

- SLOGGING WRENCHES

- OFFSET RING SPANNER FOR EXTENSION

- EXTENSION FOR OFFSET RING SPANNER

- VALVE WRENCHES

- RATCHETING RING WRENCH

- HOOK WRENCHES

- PODGING WRENCHES

- DOUBLE RATCHET WRENCH

- OFFSET DOUBLE RATCHET WRENCH

- ANGLED OPEN SOCKETS

- SOCKET DOUBLE ENDED

- AUTO WRENCH

- SWIVEL WRENCHES

- FOLDING CROSS RIM WRENCH

- CROSS RIM WRENCH

- OPEN END CROWFOOT WRENCH

- HEXAGONAL CROWFOOT WRENCH

- FLARE NUT CROWFOOT WRENCH

- TORQUE ADAPTER

- HEXAGONAL T KEYS

- "L" KEYS

- View all categories

- SOCKET WRENCHES

-

CONTROLLED TIGHTENING

- TORQUE CHECKING QC WRENCHES

- BLUETOOTH WIRELESS DATA COMMUNICATION TORQUE AND ANGLE DIGITAL QC WRENCH

- RF WIRELESS DATA COMMUNICATION TORQUE AND ANGLE DIGITAL WRENCHES

- TORQUE AND ANGLE WRENCHES

- DIGITAL TORQUE WRENCH

- ANALOGIC REVERSIBLE MINI TORQUE WRENCH

- ANALOGIC REVERSIBLE TORQUE WRENCH

- EXTENSION BAR FOR TORQUE WRENCH

- REVERSIBLE STEEL MICROMETER TYPE TORQUE WRENCH

- REVERSIBLE ALUMINUM TORQUE WRENCH

- SLIPPER TORQUE WRENCH

- TORQUE WRENCH WITH PIPE WRENCH HEAD

- INTERCHANGEABLE HEAD TORQUE WRENCHES

- OPEN END CROWFOOT WRENCH

- HEXAGONAL CROWFOOT WRENCH

- FLARE NUT CROWFOOT WRENCH

- ANALOGIC PRESET TORQUE WRENCH

- INTERCHANGEABLE HEADS PRESET REVERSIBLE TORQUE WRENCH

- ANALOGIC DIAL TORQUE WRENCHES

- PRECISION TORQUE MULTIPLIERS

- TORQUE SCREWDRIVER

- BATTERY TORQUE WRENCH

- BATTERY TORQUE WRENCH WITH TORQUE MEASUREMENT

- TORQUE NUTRUNNER

- CALIBRATION

- CALIBRATION CERTIFICATES

- TRAININGS FOR TORQUE WRENCHES

- WIRELESS TORQUE TRANSDUCERS

- INSIDE MECHANISM MANTEINANCE

- SHOW SET

- View all categories

- hydraulic tools

- PNEUMATIC TOOLS

- BATTERY TOOLS

- CUTTING

- FILES, RASPS & PUNCHES

- AUTOMOTIVE TOOLS

-

TAPS AND DIES

- METRIC SET OF 3 TAPS

- METRIC SET OF 2 TAPS

- BSW SET OF 3 TAPS

- UNC SET OF 3 TAPS

- UNF SET OF 3 TAPS

- GAS (BSP) SET OF 2 TAPS

- NPT TAPS

- ROUND METRIC THREAD DIES

- ROUND BSW THREAD DIES

- ROUND UNC THREAD DIES

- ROUND UNF THREAD DIES

- ROUND GAS BSP THREAD DIES

- ROUND NPT THREAD DIES

- REVERSIBLE TAP WRENCH

- ADJUSTABLE TAP WRENCH

- DIE HOLDER

- THREADING KITS

- View all categories

-

PIPE TOOLS

- PIPE WRENCHES

- SWEDISH PIPE WRENCHES

- REVERSIBLE CHAIN PIPE WRENCH

- HEAVY DUTY REVERSIBLE CHAIN PIPE WRENCH

- STRAP WRENCH

- ADJUSTABLE THREADERS

- DROP HEADS THREADERS

- MASTERKIT - 1

- MASTERKIT - 2

- TUBE CUTTER

- PARALLEL BENCH VICE WITH PIPE JAWS

- PARALLEL BENCH VICE

- PIPE VICE

- PORTABLE PIPE VICE

- CHAIN VICE

- TRIPOD STAND

- FOLDABLE WORKING TABLE

- View all categories

- STAINLESS STEEL TOOLS

- PIPING MACHINES

- DRAIN CLEANING AND INSPECTION

- TOOLS FOR COPPER

- TOOLS FOR PLASTIC

- TOOLS FOR WOOD

-

HAMMERS

- DEAD BLOW HAMMER

- GERMAN TYPE STONING HAMMER

- SLEDGE HAMMER

- SPANISH TYPE MALLET

- GERMAN TYPE MALLET

- BRITISH TYPE MALLET

- GERMAN TYPE MACHINIST’S HAMMER

- JOINER’S HAMMER

- FRENCH TYPE MACHINIST’S HAMMER

- BALL PEIN HAMMER

- SPANISH TYPE CLAW HAMMER

- CLAW HAMMER

- AMERICAN CLAW HAMMER

- ENGINEER’S CROSS PEIN HAMMER

- CHIPPING HAMMER

- NYLON MALLET

- BLACK RUBBER MALLET

- SQUARE COPPER MALLET

- PICKS

- View all categories

- CONSTRUCTION

-

MEASURING AND DETECTION

- MEASURING TAPES

- LONG MEASURING TAPES

- SPIRIT LEVELS

- VOLTAGE TESTER

- PRECISION MEASURING INSTRUMENTS

- PRECISION SQUARES

- DIVIDERS

- PROTRACTOR

- STAINLESS STEEL SEMI-FLEXIBLE RULERS

- WOODEN RULER

- GAUGES

- SCRIBER

- AWL

- MEASUREMENT SET

- TELESCOPIC JOINT PICK UP

- TELESCOPIC JOINT INSPECTION MIRROR

- PUNCHES

- MEASURING SET

- View all categories

- LIGHTING

- LIFTING SYSTEMS

- LADDERS

- ELECTRONIC DEVICES

- ELECTRICIAN TOOLS

- 1000V

- ESD ANTISTATIC

-

ANTIDROP TOOLS

- LANYARDS

- TOOL BELT

- 14 POCKETS NYLON BAG

- 7 POCKETS NYLON BAG

- ACCESORY FOR HAMMER

- BELT

- PLIERS

- ELECTRONIC PLIERS

- ELECTRICIAN TOOLS

- PINCERS

- ADJUSTABLE WRENCHES

- WRENCHES

- OFFSET OPEN END STRUCTURAL WRENCH

- PODGING WRENCH

- Total safety slogging wrenches

- Non sparking total safety slogging wrenches

- OPEN-END WRENCHES

- COMBINATION WRENCHES

- DOUBLE OFFSET RING WRENCHES

- ANGLED OPEN SOCKETS

- QUICK RELEASE SWIVEL HANDLE

- REVERSIBLE RATCHET HANDLE

- SWIVEL HANDLE

- INTERCHANGEABLE HEAD TORQUE WRENCHES

- SOCKET HOLDER

- SCREWDRIVERS

- FILES, RASPS & PUNCHES

- PIPE TOOLS

- CUTTING

- HAMMERS

- CONSTRUCTION

- MEASURING AND DETECTION

- LIGHTING

- INSULATED ANTIDROP 1000V

- TRAYS

- ANTIDROP TOOLS SETS

- View all categories

- 1000V INSULATED NON-SPARKING

-

NON-SPARKING

- PLIERS

- CIRCLIPS PLIERS

- MINI PLIERS

- PINCERS

- ADJUSTABLE WRENCHES

- GEAR PULLERS

- TWEEZERS

- WRENCHES

- TORQUE WRENCH

- SOCKET WRENCHES

- SET

- IMPACT SOCKET WRENCHES

- SPECIAL WRENCHES

- PIPE TOOLS

- SCREWDRIVERS

- BITS

- SHOVELS AND RAKES

- CUTTING

- FILES

- MISCELLANEOUS

- HAMMERS

- SEMI-FLEXIBLE RULERS

- GAUGES

- ALUMINIUM TOOL CASE

- atex safety sets

- SET FOR MINE REMOVAL

- ACETILEX ALLOY, safe work even in acethylene environments

- View all categories

- INTRINSIC SAFETY

- UNDERWATER USE

- NON-MAGNETIC TITANIUM

- INOX (STAINLESS STEEL) TOOLS

- PERSONAL PROTECTION EQUIPMENT

- PROMOTIONAL ITEMS

EGA Master SAFETY TOOLS

- EX DESIGNATION

-

ATEX (Atmosphere -Explosive)

2014/34/UE (ATEX 114) directive.

Harmonises legal provisions of member states for devices and protection systems for designated use in potentially explosive areas. New: ATEX 114 (old: ATEX 95).

1999/92/CE (ATEX 153) directive.

Minimum requirements for improving the health and safety protection of the worker at risk from explosive atmospheres. New: ATEX 153 (Old: ATEX 137).

Designation examples.

- Use in gaseous atmospheres: II G EEx ia IIC T4

- Use in dusty atmospheres: II 2 D T90ºC IP64

- Use for minig applications: I M2 EEx ia I

Device group

- I Mining.

- II All other explosive areas.

Category

- 1 Zones: 0/20.

- 2 Zones: 1/21.

- 3 Zones: 2/22.

- M1 Mining (In case of firedamp, continuation of operation is possible.)

- M2 Mining (Must be switched off in case of firedamp).

Atmosphere

- G. Gas.

- D. Dust.

Types of ignition protection

- o. Oil immersion.

- p. Pressurisation.

- q. Powder filling.

- d. Pressure-proof housing.

- e. Increased safety.

- ia. Intrinsic safety (required for Zone 0*). *Depends on device category.

- ib. Intrinsic safety (adequate for Zone 1 (+2).

- m. Encapsulation.

- s. Special protection.

- n. Normal operation under normal conditions (for Zone 2 only).

- nA. Non-sparking.

- nC. Protected contacts.

- nR. Carcasa resistente al vapor.

- nL. Limited energy.

- nP. Simplified.

Explosion group

- I. Methane (mining).

- IIA. Propane.

- IIB. Ethylene.

- IIC. Most dangerous group (e.g. hydrogen).

Temperature classes

- T1. 450 °C.

- T2. 300 °C.

- T3. 200 °C.

- T4. 135 °C.

- T5. 100 °C.

- T6. 85 °C.

Max. surface temperature

- Limit temperature 1=213 of min. ignition temperature of dust present.

- Limit temperature 2=min. glow temperature of dust present minus 75k (applies for layer hicknesses of up to 5mm).

The smaller value for the limit temperature must be aboye the indicated max. surface temperature of the device.

IP Code

Figure 1: contact and foreign body protection.

- 5. Protection against dust deposits.

- 6. Protection against dust penetration.

Figure 2: water protection.

- 0. (No protection).

- 1. Vertically falling drip water.

- 2. Drip water on operating device inclined to 15° 3 = spray water.

- 3. Spray water.

- 4. Spray water.

- 5. Jet water.

- 6. Strong jet water.

- 7. Temporary immersion.

- 8. Continuous immersion.

- EXPLOSION PROTECTION

-

The important principles for integrated safety explosion protection are as follows:

- Measures are taken to avoid hazardous atmospheres whenever possible.

- Measures are taken which prevent the ignition of hazardous atmospheres.

- Measures are taken which limit the explosive effect to a safe degree.

This differs from:

-

primary explosive protection.

These are precautions taken to prevent or restrict the formation of hazardous explosive atmospheres. -

Secondary explosive protection.

This covers the second group of measures, which are intended to prevent the ignition of an atmosphere that is capable of exploding.

Definition in accordance with 1999/92/EC Directive (ATEX 153) Reference values (not standardised) Zone A device from the following device category must be used (see 1999/92/EC-ATEX 153 Directive) e Area in which a potentially explosive atmosphere as a mixture of air and flammable gases, vapours or mists is present either frequently or over a prolonged period. P>1000 h/a 0 1 G Area in which under normal operation a potentially explosive atmosphere as a mixture of air and flammable gases, vapours or mists can occasionally form. 10…1000 h/a 1 2 (1G also possible) G Area in which under normal operation a potentially explosive atmosphere as a mixture of air and flammable gases, vapours wor mists is not normally present but may occur for just a short period. <10 h/a 2 3 (1G, 2G also possible) G Area in which a potentially explosive atmosphere in the form of a cloud of flammable air-borne dust is present either constantly, over prolonged periods or frequently. 1000 h/a 20 1 D Area in which under normal operation a potentially explosive atmosphere in the form of a cloud of flammable air-borne dust can occasionally form. 10…1000 h/a 21 2(1D also possible) D Area in which under normal operation a potentially explosive atmosphere in the form of a cloud of flammable air-borne dust is not normally present although may occur for just a short period. <10 h/a 22 3(1D, 2D also possible) D

- DIVISION INTO TEMPERATURE CLASSES

-

- The temperature class indication can be guaranteed only if the ambient temperature specified for the operating device is respected (see Technical Data or Rating Plate). Strict compliance is a mandatory requirement.

- Once the maximum surface temperature of any apparatus reaches the ignition temperature of the surrounding hazardous atmosphere an explosion can occur.

- Because of this, all equipment classified to Group II is divided into temperature classes. To allow for the possibility of potential hazardous atmospheres, the lowest ignition temperature must always be higher than the maximum surface temperature.

Temperature classes of flammable gases and vapours and permitted surface temperatures of the operating device in accordance with DIN EN 50014 Temperature class P>T1 T2 T3 T4 T5 T6 Ignition temperature in °C >450 >300 >200 >135 >100 >85 Maximum temperature in C° 450 300 200 135 100 85 Examples PropaneMethaneAmoniac EthyleneAlcoholsAcetylene PetrolSolvents EthyletherAcetaldehyde - Carbon disulphide

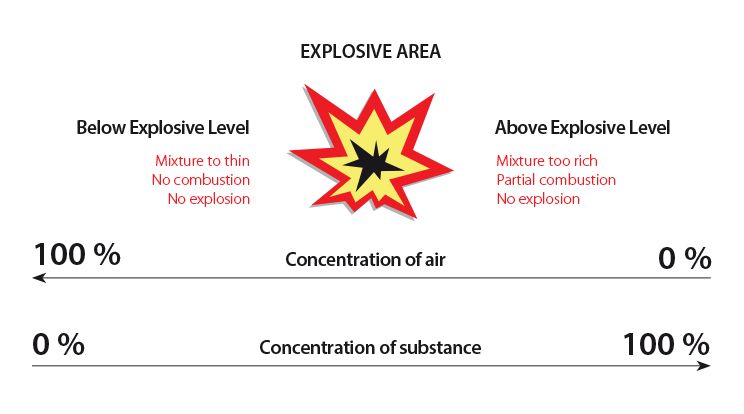

Explosions are dependent on many parameters:

Only for atmospherical conditions and pure substances sufficient comparative values and data are shown. An explosion can only occur where a flammable substance in the form of gases, vapours, smoke and dust exists along with sufficient oxygen to support -combustion and there is a source of ignition.

E.g.:

- Hydrogen: 4,0 to 77,0 % in air.

- Propane: 1,7 to 10,6 % in air.

- Ammonia: 15,4 to 33,6 % in air.

- Methane: 4,4 to 16,5 % in air.

- FUNDAMENTS OF DUST EXPLOSION PROTECTION

-

Fundamental principles

The manufacturer of operating devices for areas rendered potentially explosive through dust must indicate the maximum surface temperature of all devices that dust can penetrate (usually expressed in °C - indication of the temperature class should be avoided here).This temperature is part of the dust Ex-designation.

Designation examples: II 2 D T90 °C IP64

- II 2 D T90 °C IP64.

- If the ignition protection type is based on the housing, the housing protection rating should also be stated as an IP Cede). Or il 2 D Ex iaD 21 T96 °C.

Dust explosion protection - temperature

Combustion and explosion parameters for dusts depend on the their condition. Parameters that affect combustion and explosion behaviour include particle size, particle shape, water content, purity and where applicable the content of the flammable solvents. The particle size distribution and the mean value (value for average particle size) should also be known. In accordance with 1999/921/G Directive (ATEX 137, replacing:ATEX 118a), the system operator employer is obliged to make a hazard assessment and must therefore be aware of the minimum glow temperature of the dust.

- There are simple calculations to determine the two " temperatures " and they are carried out thus.

- Limit temperature 1 = 213 of minimum ignition temperature.

- Limit temperature 2 = +300°C - 75°K = +225°C.

These two limit temperatures must now be examined to confirm which guarantees the greater safety.

Example 1

Minimum ignition temperature = +330°C, minimum glow temperature = +300 °C.

- Limit temperature 1 = 213 x +330°C = +220 °C.

- Limit temperature 2 = +300°C - 75°K = +225 °C.

Greater safety: limit temperature (1) = +220 °C Here a device with a max. surface temperature in the event of failure <= +220 °C must be used.

As stated, the device designation includes a corresponding value.Example 2

Minimum ignition temperature = +186 °C, minimum glow temperature = +180 °C.

- Limit temperature 1 = 213 x +186 °C = +124 °C.

- Limit temperature 2 = +180°C- 75 °K = +105 °C.

- Greater safety: limit temperature (2) = +105 °C.

Here a device with a max. surface temperature in the event of failure <= +105 °C must be used.

* The value for the glow temperature applies with a dust layer thickness of 5mm. The temperature safety distance must be increased for larger layer thicknesses.

Special case: category 3 devices.

- In contrast to Category 1 and 2 devices, potential hazards in the event of failure (e.g. short circuiting, connection break etc.) do not have to be considered for Category 3 devices (for use only in Zones 2 respectively 22). The device is evaluated only in respect of hazards during normal operation, it is relatively unlikely that the device should fail at the same time as a shortterm explosive atmosphere is present No EC Type Approval Test Certificate is therefore required for Category 3 operating devices. The manufacturer may confirm that the operating device complies with the relevant standard. Nonetheless, Category 3 devices are still tested by a certified centre and. EGA Master, S.A is then awarded a declaration of conformity. (- Of course, Category 2 operating devices also offer significantly greater safety in Zones 2 respectively 22.).

- Dust explosions - albeit of a predominantly minor nature - occur relatively frequently.

- A leaflet issued by the Government Safety Organisation of the Federal Republic of Germany states: "According to documentation published by property insurers, it can be assurned that an average of one dust explosion per day occurs in the Federal Republic of Germany; around one in four of these explosions are caused by foodstuff or animal feed dusts". Dust explosions are a world-wide problem. Between 1980 and 1990 in the USA, for example, some 200 serious foodstuff or animal feed related dust explosions were recorded, causing 54 deaths, 256 injuries and property damage amounting to 165 million US dollars.

IGNITION SOURCES BY ELECTRICAL OPERATING DEVICE TYPE

- 9 % static electricity.

- 9 % glow source.

- 11,5 % unknown.

- 3,5 % electrical equipment.

- 2,5 % other.

- 30 % mechanical sparks.

- 5 % welding.

- 6 % auto ignition.

- 6,5 % hot surface.

- 8 % fire.

- 9 % friction.

DUST EXPLOSIONS BY DUST TYPE

- 34 % wood.

- 6 % other.

- 2 % paper.

- 10 % metal.

- 10 % coal.

- 14 % plástic.

- 24 % corn.

- Electrical operating devices represent only a small proportion of the ignition sources found to cause dust explosions, not least due to the safety stipulations in the regulations for erecting electrical plants in potentially-explosive areas.

- The introduction of the (Regulation on electrical plants in potentially-explosive areas) - ElexV" [1.4] in 1980 specified a type examination certificate for electrical operating devices used in zone 10 (from 01.07.2003 in zones 20 and 21).

- "Dust explosion-protected" operating devices, the surface temperatures of which lies below the acceptable limit for standardised dust thickness of 5mm, can, despite the existence of an official test certificate, become a danger source if, contrary to the conditions, they become covered or completely encased with a thick layer of dust.

- TYPES OF IGNITION PROTECTION

-

Ignition protection type "n"

- Ignition protection type "n" is applicable only for Category 3 operating devices used in areas rendered potentially explosive by gases. Because only normal operation and no equipment failures are considered here, small differences occur in the designation for ignition protection type.

NA: non-sparking electrical equipment (revolving machines, fuses, lamps, gauges and equipment with low energy).

NC: sparking equipment or equipment with hot surface under operating conditions (dosed indexing mechanism and non-ignitable components, air-tight equipment, leak-proof sealed equipment).

NR: vapour-proof casing.

NL: equipment and circuit with limited energy.

NP: simplified overpressure casing.

Form of ignition protection Schematic description Basic principie Standard General

General provisions for the design and testing of electrical equipment which is designed for the ex range. EN 50014 Increased safety e

Only applies to equipment or the components of which usually do not generate sparks or arcs, do not adopt dangerous temperatures and the mains voltage of which does not exceed 1 kV. EN 50 019IEC 60 079-7FM 3600UL 2279 Pressure-proof casing d

In the case of an ignition inside the casing, the explosion is contained within the casing. EN 50 018IEC 60 079-1FM 3620UL 2279 Pressurisation p

Ignition source is sealed in by an ignition protection gas which a under overpressure (mind, 0.5 mbar) Ignition protection gas the environment atmosphere cannot enter. EN 50016IEC 60 079-2FM 3620NFPA 496 Intrinsic safety i

By restriction of the energy in the circuit the development of inadmissibly high temperatures, ignition sparks and arcs are avoided. EN 50 020IEC 60 079-11FM 3610UL 2279 Oil immersion o

Equipment or parts of the equipment are put into an oil casing - by which they are separated from the ex atmosphere. EN 50 015IEC 60 079-6FM 3600UL 2279 Powder filling q

Ignition source encased by fine-grained sand -the enviroment ex atmosphere cannot be ignited by an arc. EN 50 017IEC 60 079-18FM 3600 Encapsulación m

By encapsulating the ignition source into a grouting material, it cannot ignite an ex atmosphere. EN 50 028IEC 60 079-18FM 3600UL 2279 Non-incendive n Zone 2.In this form of ignition protection multiple methods of ignition are combined. Slightly simplified application of other zone-2 forms of ignitioh protection - “n” stands for “non-incendive”. EN 50 021IEC 60 079-15 IP protection

- Identification letters.

- Protection against penetration by foreign bodies and dust (1st identification letter) *.

- Protection against penetration by water (2nd identification letter) *.

- Additional letter.

- Supplementing letter.

(*) Should no degree of protection be specified, then the characters are replaced with the letter X. E.g. IP X4.

1st ident letter Degree of protection Symbol 0 No protection. 1 Protection against penetration by large foreign bodies, 0>50 mm. No protection against intentional access. 2 Protection against small foreign bodies, 0>12,5 mm, exclusion of fingers or similar objects. 3 Protection against small foreign bodies, 0>2,5mm, exclusion of tools, wires or similar objects. 4 Protection contre des particules granuleuses, 0>1mm, hors outils, cables ou objets similaires. 5 Protection against dust deposits (dustprotected), complete exclusion of access.

6 Totally protection against dust deposits (dust protected), complete exclusion of access.

1st ident letter Degree of protection Symbol 0 No protection. 1 Protection against drops of water falling vertically (water drop).

2 Protection against water falling at an angle (water drop), inclined at 15° to the normal operating position.

3 Protection against water spray, up to 60° from the vertical. 4 Protection against water splashes from any direction.

5 Protection against water jet from any direction

6 Protection against heavy sea or strong water jet (Flooding protection). 7 Protection against submersion in water at a certain pressure and for a certain period.

8 Protection against continuous submersion in water.

Aditional letter Significante (facultative) Supplementing letter Significante (facultative) A Back of the hand. H High voltage apparatus. B Finger. M Machine running. C Tools. S Machine not running. D Wire. W Weather conditions.

(*) Should no degree of protection be specified, then the characters are replaced with the letter X. E.g. IP X4.

- DIVISION INTO ZONES

-

Safety is our first priority.

At all places where inflammable substances are produced, processed, transported or stored, safety is extremely important - especially in the chemical and petrochemical industry, in oil and natural gas production and in mining.In order to provide the highest level of safety possible, most state’s legislations have developed corresponding conditions in the form of laws, regulations and standards. In the course of globalisation, enormous progress could be made in uniform guidelines for explosion protection, It is the European Union that is leading the way. The 94/9/EG guideline lays the foundation for a complete unification. As of 01 july 2003, all new devices must be approved in accordance with this guideline.

Meaning of the zone classification

- Zone 0/20: danger is always present, for a long time or frequently.

- Zone 1/21: danger is occasionally present.

- Zone 2/22: danger is seldom present or present for a short time.

- Safe area.

- Zone 2.

- Zone 1.

- Zone 0.