TIGHTENING FUNCTION

Screwed tightening or threaded joint’s function is to fix joining structural elements, transmitting motor or braking forces, or sealing containers of liquid and gas containment. It represents one of the most common procedures in assembling or assembling parts.

The fundamental element is the screw, which can be described as a threaded bolt equipped with a head that serves for drag and anchoring. There are also other threaded elements for the joint (bolts, nuts...)

WHY IS ITS CONTROL IMPORTANT?

To ensure proper fixation of the elements during the service time required by each application, the threaded joining elements must be carefully sized, as they must withstand high clamping forces and static and dynamic stress.

The goal for the joined pieces is to behave as if they were a single piece, with no relative movements.

To do this, an adequate tension force must be applied to the joint, which is achieved when the screws are tightened.

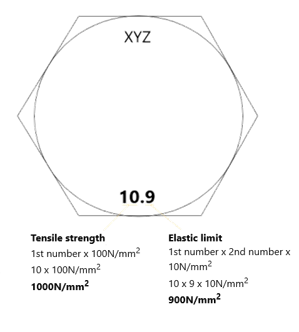

The correct selection of tightening elements not only dimensions need to be considered, but also in terms of their mechanical strength. The mechanical resistance categorization code includes 2 elements.

- The first of the numbers indicates the tensile strength (multiplied by 100, gives us the result in N/mm2);

- The second number indicates the elastic limit (multiplied by the first number and by 10, gives us the result in N/mm2).

In the example below, the tensile strength would be 1000N/ mm2 (10x100) and the elastic limit would be 900N/mm2 (9x10x10).

Service life, performance, operating costs, and safety are affected if the appropriate axial stress is not applied during tightening.