When purchasing a tool or machine for use in explosive environments, it is important to be clear about the characteristics of these environments.

Working in a Zone 0/20 is not the same as working in one that is classified as Zone 1/21 or Zone 2/22.

Likewise, if the explosive atmosphere may be caused by dust or gas.

In addition, within these two elements, it is important to be clear about their specific quality, i.e., whether it is methane, acetone, or hydrogen gas.

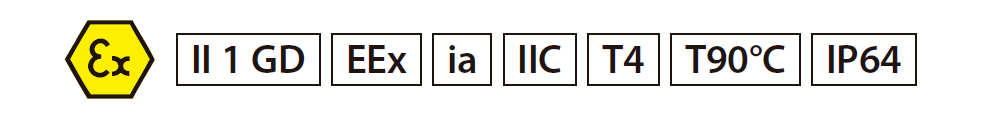

That is why, in the means used in ATEX zones, they come with a designation like the one shown below:

Would you know how to interpret these ATEX designations?

Let's see

ATEX DESIGNATIONS

Let's go from left to right knowing the meaning of each of these designations.

EX: Indicates that the product is suitable for use in explosive environments.

Device group:

- I: For use in mining

- II: All other explosive areas.

Category:

- 1: For use in Zones 0/20

- 2: For use in Zones 1/21

- 3: For use in Zones 2/22

- M1: For use in mining, and even if firedamp is detected, it can still be used.

- M2: Also for mining, but in this case, if firedamp is detected, it must be turned off.

Atmosphere:

- G: Gas

- D: Dust

II 1 GD, therefore, could be interpreted as an ATEX device, which could be used in all other explosive atmospheres (except mining), which is for use in Zones 0/20, and which can be used both in an explosive atmosphere generated by gas and by dust.

As for the designation "ia", it refers to the types of protection against ignition:

- O: oil immersion

- P: Pressurization

- Q: Dust Filling

- D: Pressure resistant housing

- E: Increased safety

- IA: Intrinsic Safety (required for Zones 0, although it depends on the category of the apparatus)

- IB: Intrinsic Safety suitable for Zones 1 and 2

- M: Encapsulation

- S: Special protection

- N: Normal operation under normal conditions (only for Zone 2)

In our example, the ATEX device would be a means of intrinsic safety required for Zone 0.

The next designation (IIC) refers to explosion groups, which we discussed in our post Explosive atmospheres and their risks. How can we deal with them?

In this case, it is suitable for areas where there are very unstable gases such as hydrogen.

T4, is a denomination that speaks of temperature classes or concretely, of the maximum surface temperature in which the gas can penetrate in the case of failure of the apparatus.

- T1: 450°C

- T2: 300°C

- T3: 200°C

- T4: 135°C

- T5: 100°C

- T6: 85°C

In our case, the maximum surface temperature would be 135ºC that gas can penetrate in case of technical failure.

T90 refers to the maximum surface temperature that can be reached by an explosive atmosphere in the event of a device failure (or during normal use in the case of category 3 devices).

In our case, in the event of a failure of our ATEX tool, the maximum temperature that the surface can reach is 90°C.

Finally, the IP 64 designation, which would be divided as follows:

- 6

- 4

The first number is a datum provided for equipment used in areas defined as potentially explosive by dust.

- 5: Protection against dust deposits

- 6: Protection against dust penetration

The other number refers to protection against water.

- 0: No protection

- 1: Vertical water dripping

- 2: Water dripping on the unit in operation at an inclination of 15°.

- 3 and 4: Water spray

- 5: Water jet

- 6: Strong water jet

- 7: Temporary immersion

- 8: Continuous immersion

This designation would therefore mean that the tool is protected against dust penetration as well as water spray and water jet.

Would you like to learn more about ATEX?

Watch our ATEX webinar by our experts.

Or write to us and we will be happy to conduct a training course with you.